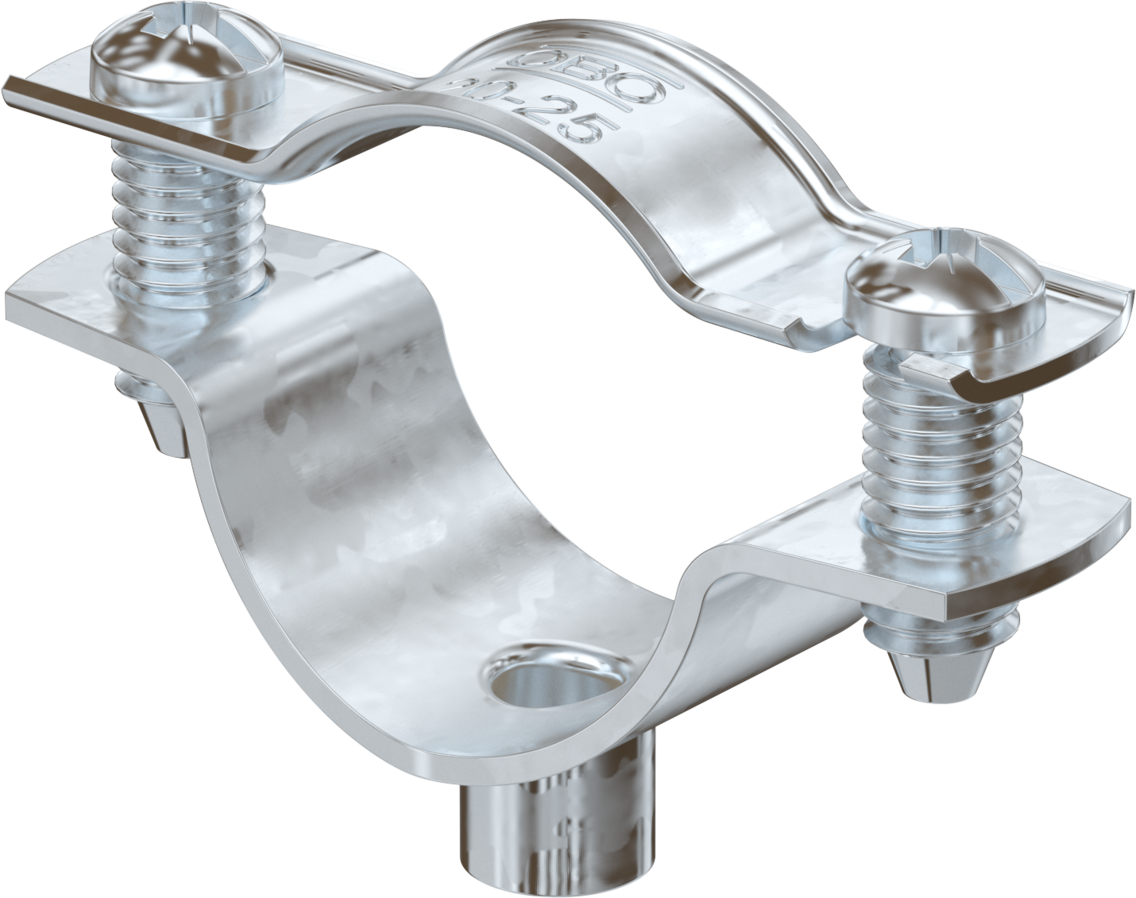

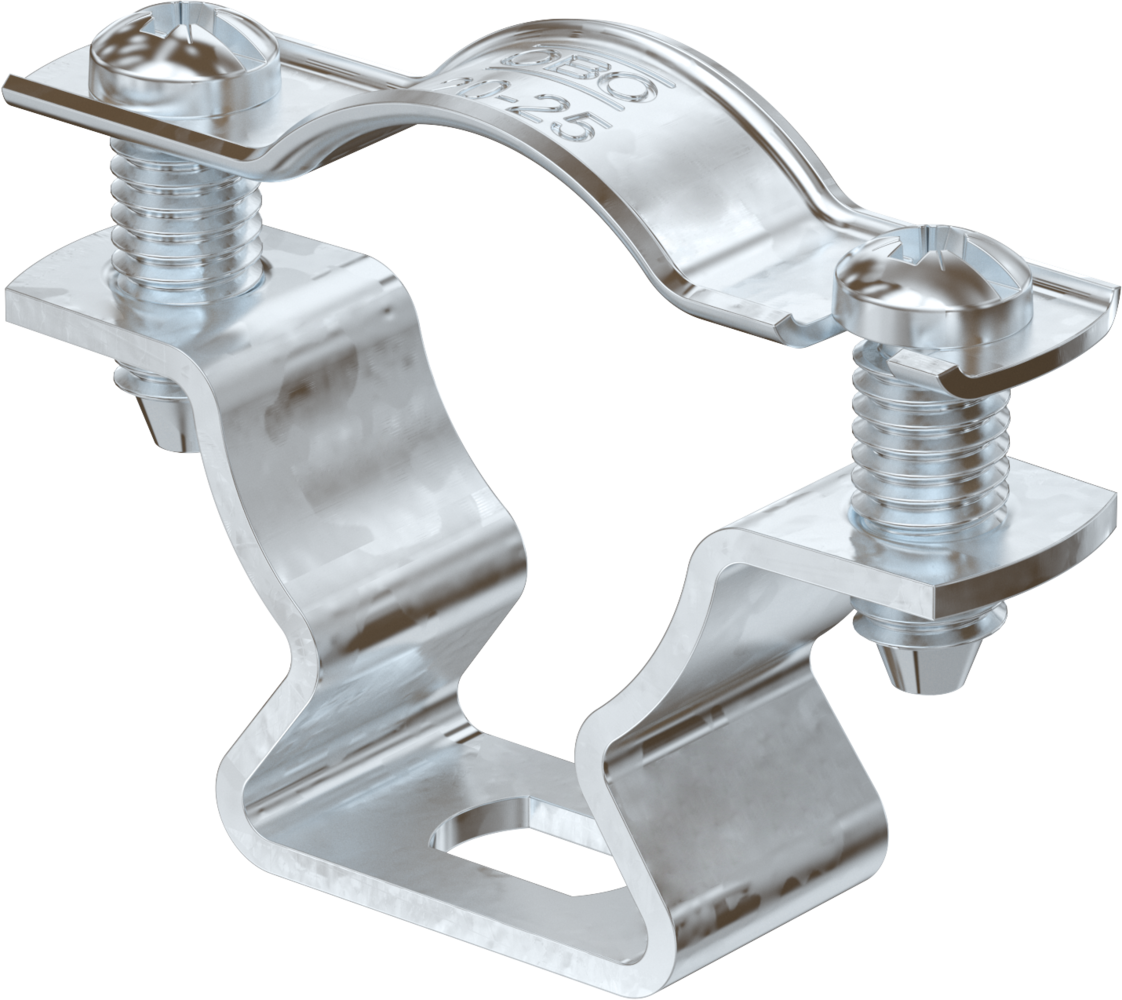

The ASG 732 and ASL 733 spacer clips: Slimmed-down product range and increased flexibility

The OBO cable spacer clips, type 732 / 733, can now present themselves in a completely redesigned portfolio. The previous product range has been replaced with the new models, ASG 732 and ASL 733. The reworked spacer clip product range stands out through:

- A larger selection of materials and surfaces

- An expansion of the clip clamping ranges, allowing a reduction in the number of variants of fastening clips

- The reworking of the spacer clips creates a larger range of use options and installation environments

- Secure fastening of cables and pipes to walls, floors and ceilings

Extended use options through large selection of surfaces

The previous 732 spacer clips were available in galvanised and A4 stainless steel versions, whilst the new ASG 732 clips are now also available with a hot-dip galvanised surface and in A2 stainless steel. The more robust surfaces and the finer material of the stainless steel clips increasingly allow the clips to be used more in exterior areas and with increased corrosive loads. The spacer clips of type ASL 733 are available in galvanised, hot-dip galvanised, A2 and A4 stainless steel and aluminium versions.

Optimised shape of the spacer clips provides flexibility

With the reworking of the portfolio, the shape of the spacer clips was also optimised, meaning that the clips have a larger clamping range and can be used even more flexibly. A single clip can now accept an even larger range of cable diameters. This also allowed the product range to be slimmed down considerably. Of course, all the available cable diameters are covered with the clip range.

- Clips, type ASG 732: Cables with diameters from 8 to 63 mm can be clamped. A total of 14 different clip sizes are available.

- Clips, type ASL 733: Suitable for cables with diameters from 6 to 63 mm. 11 clip sizes are available here.

Thanks to the optimised portfolio, the number of fastening clips required on the building site has been reduced. Installation engineers and craftspeople can react just as flexibly to the on-site requirements but need fewer clips. This not only simplifies the work on the construction site, but also means simplification in the procurement and warehousing of spacer clips.

New, intelligent product detail: Self-locking cover

The new clips are equipped with a self-locking cover.

Worked-in beading on the cover ensures that the clip cover cannot come undone ‒ even if the connection screw becomes loose due to mechanical influences. In addition, the worked-in beading serves as cable protection, both during and after cable routing.

How are the spacer clips fastened?

The clips are fastened with different materials, depending on the type and substrate. Thus, the ASG 732 spacer clips posses an M6 female thread in the bottom of the base for mounting, which can be screwed directly onto a nail anchor or bolt tie. By contrast, the clips of type ASL 733 can be mounted using a slot with standard fastening materials. This allows the use of screw ties, spreading anchors, universal anchors, all-purpose anchors and sprint screws. In the sizes 8‒17 mm, the ASL 733 spacer clips possess protrusions in the base ‒ so-called ribs ‒ through which the anchors and screw head can be passed through easily. This also allows the easy fastening of smaller clips.

Besides direct wall mounting, there is also the option of fastening the spacer clips on components, for example with washers on profile rails or cable sections.

Overview of the benefits of the cable spacer clips:

- Robust and stable: The spacer clips stand out through their very high resilience and load-bearing capacity. In particular, the stainless steel variants are extremely robust, as they do not get deformed as often and have a greater resistance to corrosion.

- On the safe side: All the spacer clips of type ASL 733 and ASG 732 in the galvanised, hot-dip galvanised, A2 and A4 stainless steel versions are tested and approved for the maintenance of electrical function according to DIN 4102 Part 12, maintenance of electrical function classes E30 to E90.

- Extremely versatile: The large range of materials in the new portfolio produces countless use options for the spacer clips.

- Slimline product range with all the benefits: The product range was slimmed down considerably, but the high functionality remains and all the cable diameters are covered.

- Simpler working on the building site and in the warehouse: The new spacer clip portfolio means that installation engineers can react more flexibly on the building site. Warehousing has also been simplified considerably.